E-mail: jack@fadvanlashes.com

E-mail: jack@fadvanlashes.com Whatsapp: +8613165083432

Whatsapp: +8613165083432 E-mail: jack@fadvanlashes.com

E-mail: jack@fadvanlashes.com Whatsapp: +8613165083432

Whatsapp: +8613165083432At Fadvan, we've always embraced the spirit of craftsmanship and the pursuit of perfection in our eyelash production process. When it comes to selecting eyelash materials, we're committed to continuous exploration and improvement.

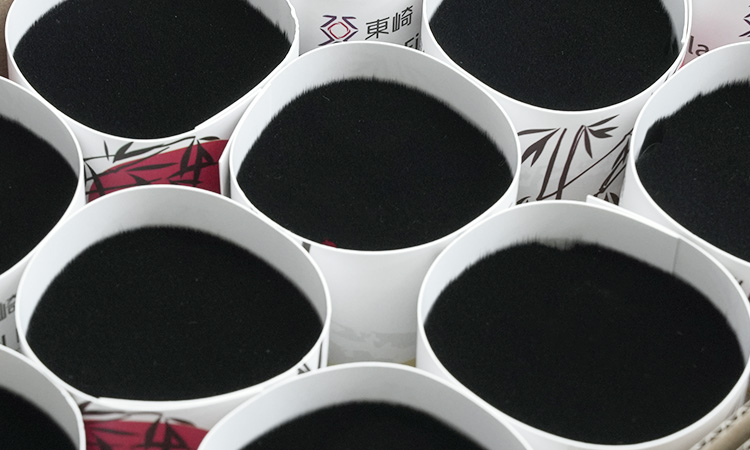

As the times change, so do people's eyelash preferences. While we supply eyelashes worldwide, we've also actively sought customer feedback and experiences. Through the dedicated efforts of our professional R&D team, we've introduced a more user-friendly, ethically sourced, and highly popular material—cashmere.

· Uniform diameter

· No color variation

· Matte finish for a more natural look

· Soft and lightweight

· Stable curvature

· Consistent quality

Advantages: Stable quality, uniform diameter, natural matte color, no color variation, stable curvature.

Disadvantages: Slightly stiff material, expensive pricing.

Advantages: Stable quality, uniform diameter, consistent curvature, moderate pricing.

Disadvantages: Slightly stiff material, very dark and shiny color, unnatural appearance.

Advantages: Stable quality, uniform diameter, natural matte color, no color variation, stable curvature.

Disadvantages: Slightly stiff material, expensive pricing.

Advantages: Uniform diameter, no color variation, affordable pricing.

Disadvantages: Unstable curvature, slightly stiff material, tendency for color to turn gray, unnatural appearance, inconsistent quality.

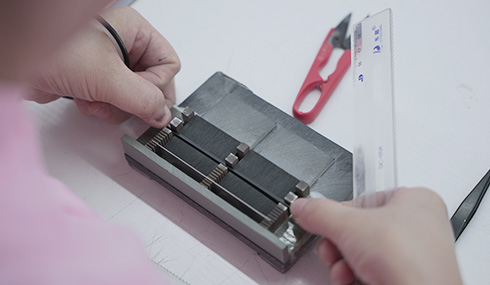

Fadvan operates four factories established in 2005, specializing in the production of false eyelashes. Our facilities cover 2,000 square meters, employ 120 staff members, and oversee the entire production process, from R&D, raw material procurement, manufacturing, inspection, eyelash packaging, to export.

With a daily production capacity of approximately 20,000 boxes and a warehouse stock of 500,000 boxes, we boast a highly skilled workforce, stringent quality control, effective management, and a sharp understanding of the American beauty market. Each box of our eyelashes meets international standards.

Order a sample pack so you can feel our premium range of lashes for yourself.